Horizontal Vacuum Filter Belts

HVBF – Built for Efficiency and Durability

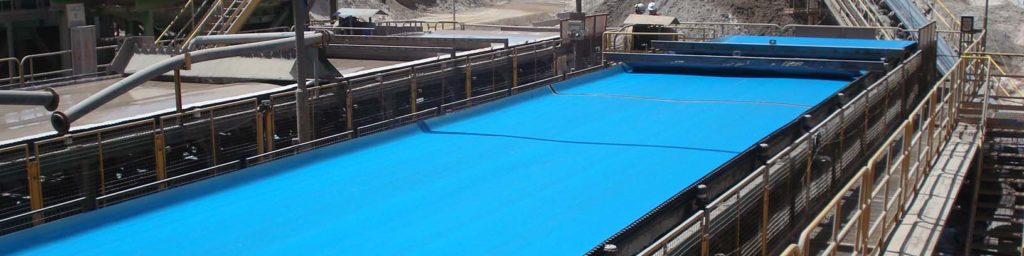

Clear Edge offers industry-leading Horizontal Vacuum Filter Belts designed for exceptional liquid-solid separation across diverse sectors. With decades of experience, our durable and reliable filter belts are widely used in Mining and Minerals, Chemicals, Power Generation, Food and Beverage, Building Products and Pulp and Paper industries. Engineered to deliver high performance, our durable Vacuum Filter Belts ensure operational efficiency and optimal filtration results for various industrial processes. Discover our advanced filtration solutions tailored to meet your specific needs for efficient, high-performance industrial filtration process.

Why Choose Clear Edge Vacuum Filter Belts?

We engineer Filter Belts designed for continuous movement and maximum performance. As slurry is introduced onto the filter belt, filtration occurs through a vacuum beneath the belt, which travels toward the discharge end to release the filter cake. Our uniquely crafted fabrics, yarns, and weaves ensure smooth cake release and superior abrasion resistance, contributing to a long operational life ensuring efficiency and durability.

One key advantage of our filter belt system is its visibility, allowing operators to easily monitor the process and quickly identify any deviations. Utilizing Clear Edge filter cloth is a cost-effective choice due to its low maintenance and easy cleaning features. We offer both single-layer and double-layer filter belts, continuously innovating to enhance dimensional stability, high flow rates, and extended service life.

Boost your filtration efficiency with our reliable Horizontal Vacuum Filter Belts

Yarn Type and Characteristics

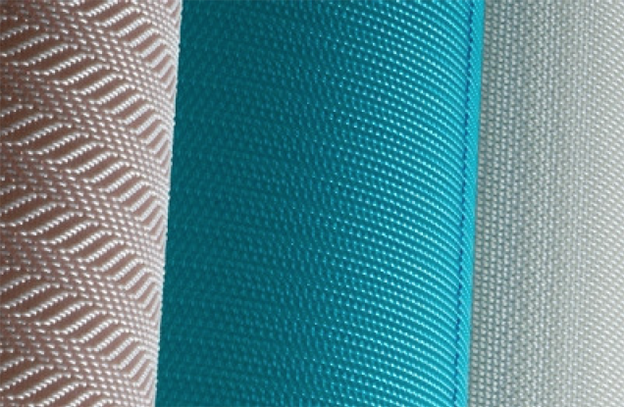

Clear Edge offers optimal choices of Belt filter fabric using a wide variety of yarn materials including Polypropylene, Polyester, and other types with specially developed weave structures. Monofilament, multifilament and staple fibres help optimise your process. With excellent particle capture, resistance to binding, smooth cake release and flexibility, our customers rely on our filtration solutions.

Weave

At Clear Edge, we offer a range of weave patterns based on your application. We work with customers to develop the correct weave type based on flow rate, cake release, caption level and blinding.

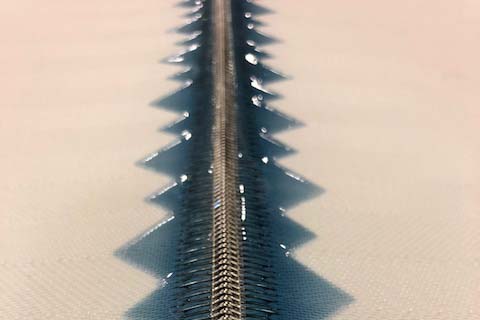

Seaming Options

We deliver seams with stability for a continuously smooth filtration process. Our ranges include various clipper seam systems with or without specifically designed flaps for belt sealing, various clipper resin protections and designs. We develop and select the right seam for your application.

Clear Edge belts are valued by end-users and OEMs running these horizontal vacuum filter belts:

- Andritz

- Compositech-Filters

- Delkor

- Eimco

- Filtres Philippe (Hasler)

- FLSmidth

- Gaudfrin

- Jord

- Nuclear Industry Yantai Tongxing Industrial Co., Ltd.

- Pannevis

- Tema

- ThyssenKrupp

- WesTech

- Many others

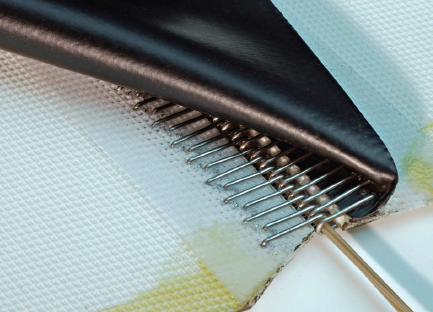

Abra-Seal™ Seam

Abra-Seal™ Seam technology has been proven to increase filter belt life on horizontal and rotary vacuum filters while preventing seam leakage. Abrasive slurry conditions in combination with high flow rates are common in belt filtration applications ranging from FGD, Fine Sand Dewatering, Phosphoric Acid and various chemical applications. Turbulence is particularly evident at the critical seam area of the belt where rates increase through metal fasteners. Centrifugal abrasive action occurs at the center seam area of the filter belt at both the leading and trailing ends. This action combined with abrasive particles in the slurry results in localized premature wear and failure of the filter belt.

Conventional seam and flap configurations offer no enhancement to this area. Primitive cloth flaps with bulky Velcro seals provide temporary protection, but often over flex and work their way open while riding over the equipment’s rolls.

The Abra-Seal™ Seam incorporates a low-profile impermeable sealing panel to eliminate leakage at the clipper seam. The panel’s half octagon shape provides a resilient wear zone protecting against abrasive centrifugal action. This proprietary shield outlasts all current belt seaming technology, saving expensive belt replacement, down time and maintenance costs.