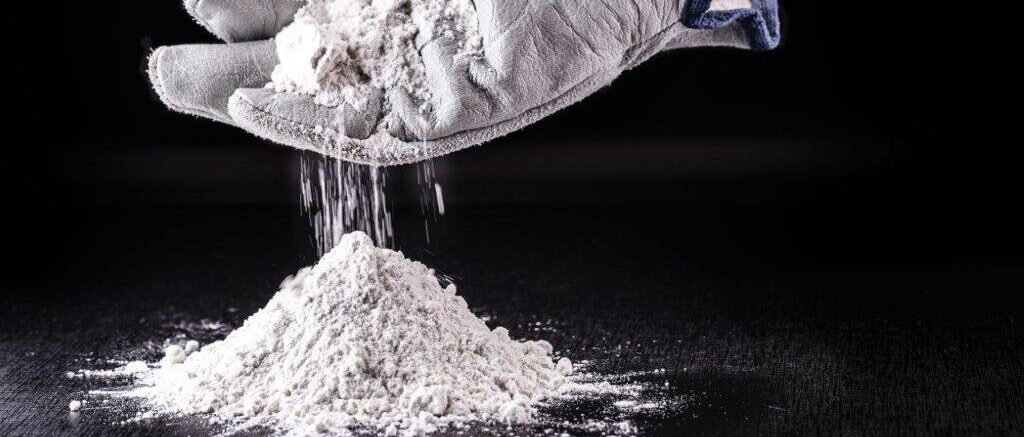

Titanium Dioxide

Clear Edge has been serving many titanium dioxide producers across the world over many decades and considered having best available filtration solutions. Our woven media is manufactured to exacting standards using highly technical raw materials. Specialized finishing techniques ensure that our filtration and diaphragm media meet the tight tolerances demanded from the varied TiO2 refining processes.

The Clear Edge product range has been developed along-side our titanium dioxide producing partners with all refining methods and related process stages catered for. Whether it is Sulphate or Chloride process and its filtration stages, we have your filter media needs covered. Typical filtration or woven media dependent applications may include:

- Sulphate process

- Digestion

- Pre/Post Leaching

- Pre-Calcination

- Pigment Washing

- Gypsum Dewatering

- Chloride process

- Chlorination

- Finishing

Our woven media range is designed using all types of polymers and fibers to meet not only the process demands, but also the specific demand of each type of equipment found in the titanium dioxide refining industry, these include:

- Horizontal chamber press

- Vertical tower press

- Moore Leaf vacuum filter

- Rotary vacuum drum

- Rotary vacuum disc

- Horizontal vacuum belt filters

- Dust collectors

Clear Edge have designed fabrics from highly technical polymers that can withstand the aggressive conditions that can be encountered. Fabric selection is scientifically based on our extensive knowledge of the thermal, chemical and mechanical conditions found in the applications. Vertically integrated manufacturing ensures the highest standard of quality at every stage. In addition, our fabrication team has developed smart solutions for the fast and simple fitting of Vacuum (MOORE) Leaf bags used in the TiO2 industry.

For full specifications, download the Clear Edge Titanium Dioxide brochure

Request More Information