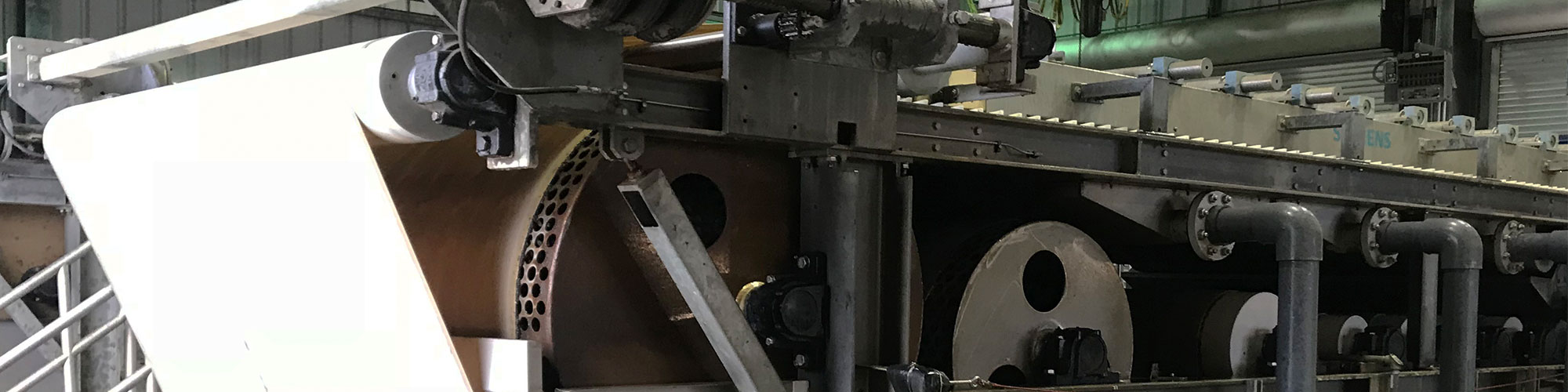

Press Belts

Commonly found in municipal wastewater treatment plants, industrial treatment plants, pulp and paper as well as the beverage sector, Clear Edge works with customers worldwide to develop fabrics for press belt machines. We tailor filtration specifications to individual applications and needs.

The press belt is distinguished from other traditional methods of filter belts because it is built with several layers for a multi-stage dewatering process. In wastewater treatment plants, this is vital for high quality filtration to ensure the results from the slurry separation phase meet all environmental requirements. The slurry is conveyed along the press belt and dropped toward the middle of the machine and sandwiched between two press belts. The roller within the machine forces excess water or liquid out of the slurry before the cake is collected in the bin.

Key Benefits of the Clear Edge Press Belt

- Decades of experience with key market sectors

- High filtration efficiency and throughput

- Robust materials for long operational life

- Selection of woven and spiral weaves available dependent upon your end product

- Smooth cake releases and cleaning

- Strong resistance to blinding

- Support for tailoring fabrics to individual applications including municipal wastewater treatment and beverages such as fruit juices and vegetable puree

Clear Edge belts are valued by end-users and OEMs running these belt presses:

- Alfa-Laval (Ashbrook Simon-Hartley)

- Andritz

- BDP

- Bellmer

- Compositech-Filters

- Dewaco

- EMO

- Evoqua (Sernagiotto)

- Komline-Sanderson

- Phoenix Process Equipment

- Many others