Lithium Filtration

Our innovative filter fabrics, designed for efficiency and sustainability, help optimize every stage of the process. Backed by world-class support from design to installation, Clear Edge ensures reliable performance to take your operations to the next level.

Enhancing Efficiency and Purity in Lithium Processing

We deliver advanced filtration solutions that enhance efficiency, sustainability, and performance in lithium extraction and battery recycling. Our industry-leading filter fabrics maximize product purity, boost production efficiency, and improve material recovery rates—critical for the rising demand in energy storage.

By collaborating with industry leaders, pilot plants, and OEM partners, we gain early access to testing and optimize filter cloth selection. Our material science-driven approach ensures superior performance across all our filter media. With Clear Edge, you get:

- Fast on-site process analysis

- Dedicated local support

- Extended filter life

Together, we can make a lasting impact on the circular economy and the future of clean energy.

Ask Us About Our Latest Innovation

Our Value Proposition

Clear Edge is unified by a singular drive; we take on our customers biggest process filtration problems and solve them through the material science designed into our products.

Clear Edge’s Role in Lithium Filtration

Lithium extraction falls into two main categories, hard rock and brine evaporation. Both hard rock and brine extraction processes have multiple filtration stages within. In addition to the extraction processes, Lithium is also increasingly obtained from Li-ion battery recycling.

Hard Rock (Spodumene Concentration & Conversion)

Lithium from spodumene ore is concentrated through flotation and thickening, followed by de-watering with specialized filter cloths. Thermal conversion makes lithium extractable, after which sulfuric acid and heat produce Lithium Sulphate. Thickeners separate waste, precipitation removes impurities, and filtration refines Lithium Carbonate, ensuring high recovery and consistency.

Our Filter Fabric Range for Diverse Applications and Filter Equipment:

- Spodumene Concentrate de-watering – FILTER PRESS, HVBF

- Tailings de-watering – TOWER PRESS, FILTER PRESS

- Aluminosilicates / Gypsum removal – HORIZONTAL VACUUM BELT FILTER, RV DRUM

- Impurities removal – FILTER PRESS

- Lithium Carbonate de-watering – FILTER PRESS

Brine Evaporation

Lithium-rich brine reservoirs are extracted and pumped into evaporation ponds, where solar evaporation concentrates lithium salts like Lithium Carbonate or Lithium Chloride. Multiple filtration and purification stages remove impurities before converting lithium into battery-grade Lithium Hydroxide or Lithium Carbonate.

Our Filter Fabric Range for Diverse Applications and Filter Equipment:

- Impurities Removal – HORIZONTAL VACUUM BELT FILTER

- Lithium Carbonate Polishing – PRESSURE LEAF FILTER

- Clarification – HORIZONTAL VACUUM BELT FILTER

Direct Lithium Extraction (DLE)

DLE technology offers a sustainable alternative, using selective absorbents to extract lithium while rejecting impurities. The lithium solution undergoes polishing, chemical processing, and advanced filtration, producing high-purity Lithium Carbonate and Lithium Hydroxide while minimizing environmental impact.

Our Filter Fabric Range for Diverse Applications and Filter Equipment:

- Fresh Brine Filtration – LINEAR SCREEN

- Impurities Removal – HORIZONTAL VACUUM BELT FILTER

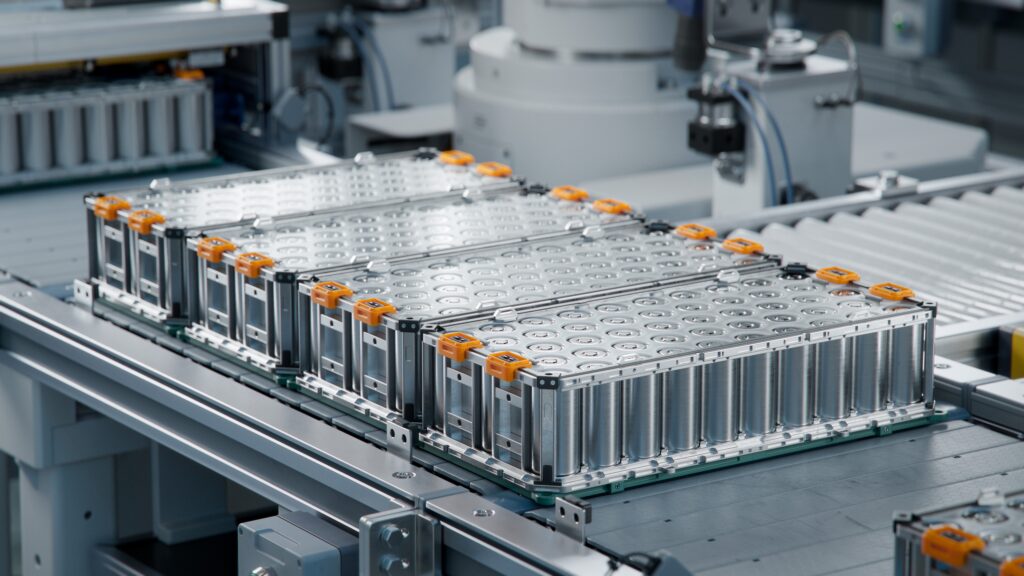

Battery Recycling

As EV battery demand grows, recycling plays a crucial role in advancing the circular economy. Used Li-ion batteries are disassembled, crushed, and leached, creating Black Mass—a mixture of valuable metals. Through filtration and separation, lithium compounds are recovered and processed into Lithium Carbonate or Lithium Hydroxide, ensuring resource efficiency and sustainability in battery production.

Our Filter Fabric Range for Diverse Applications and Filter Equipment:

- Liquid Electrolyte Filtration – HORIZONTAL VACUUM BELT FILTERS

- Post Leach – FILTER PRESS

- Separation / Purification – FILTER PRESS

- Final Product De-watering – FILTER PRESS

Proven Filtration Solutions: Real-World Case Studies

Clear Edge Filter Fabric Brings Remarkable Gains in Lithium Purity and Reduced average NTU.

40% Reduction in Silica Impurities, Leading to Full-Scale Adoption of Azurtex™ 2.0 Filter Cloth.

Clear Edge Is Your Trusted Partner for Filtration Solutions.

Committed to Industry Excellence

“Clear Edge Filtration is a proud member of the International Lithium Association (ILiA), reinforcing our commitment to advancing responsible lithium production and battery recycling. As an ILiA member, we stay at the forefront of industry innovation, ensuring our filtration solutions meet the evolving demands of lithium extraction and processing.”

Lithium Filtration Brochure

Filtration Expertise with a Global Footprint

Material Science By Clear EdgeTM

Our team of dedicated scientists and engineers harness the power of advanced materials to push the boundaries of filter cloth & belt performance, ensuring we stay at the forefront of filtration technology.

Worldwide Production and Support

Clear Edge operates a global network of production facilities and expert teams, ensuring seamless manufacturing, fast delivery, and localized technical support for high-performance filtration solutions tailored to industry needs.