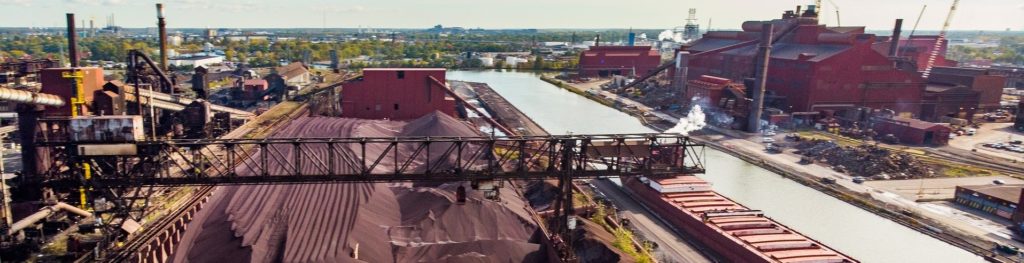

Iron Ore

Clear Edge have been supplying filter media into the Iron Ore industry for many years. We have worked closely with industry leaders to understand the operational demands of iron ore beneficiation from Magnetite and Hematite, concentrate and tailings de-watering as well as the iron ore pelletising process.

We have developed a range of fabrics that consistently perform to a high level. Whether that is lowering the moisture content of transported concentrate, or increasing the service life a filter bags through improved abrasion resistance and dimensional stability, Clear Edge has the product to elevate your TCO to the next level.

Our fabrics are designed for the individual demands of each equipment type used in the industry E.g. HORIZONTAL CHAMBER PRESS, TOWER PRESS, ROTARY VACUUM DISC FILTER and HORIZONTAL VACUUM BELT FILTERS, offering process performance benefits such as:

- Excellent retention efficiency

- Reduced cake moisture

- Extended filter media life

- High flow rates & production throughput

- Reduced blinding tendency

- Superior filter cake release

- Increased dimensional stability

For full specifications, download the Clear Edge Iron Ore brochure

Request More Information