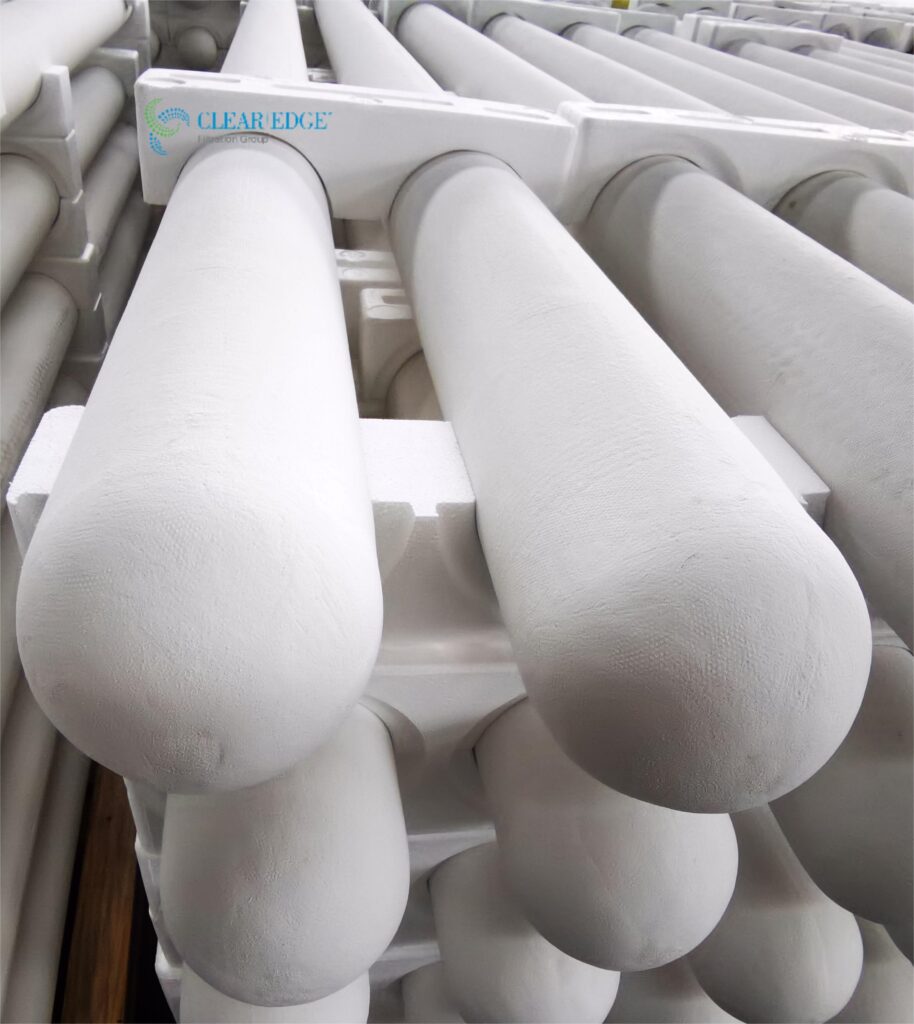

Cerafil® Ceramic Filter Elements

Designed to withstand extreme temperatures and corrosive gases, Cerafil® provides reliable long-term particulate and gas removal, protecting downstream processes, reducing operational costs, and delivering clean, sustainable air solutions across diverse high-temperature industrial processes globally.

Advanced hot gas filtration for particulate and hazardous gas removal

Cerafil® ceramic filter elements are engineered for the highest performance in hot gas filtration. They remove particulate matter such as dust, smoke, and fumes, as well as hazardous gases including NOx, dioxins/furans, CO, and VOCs from elevated-temperature gas streams.

Developed using a precision injection-molding process, Cerafil® filters feature a dense outer surface that promotes cake filtration, prevents dust penetration, and ensures excellent filtration efficiency. Made from alumino-silicate fibers, they offer outstanding thermal resistance and durability even in the most demanding environments.

Since their launch in 1990, Cerafil® filters have proven their value in over 300 projects worldwide.

Product Portfolio

The Cerafil® product portfolio comprises two distinct categories:

- Non-catalytic filters (for particulate matter removal)

- Catalytic filters (for particulate matter removal and gaseous pollutants such as NOx, Dioxin/Furan, CO and VOCs removal)

Non-catalytic filters

Cerafil® XS Series

- 99.99% dust removal efficiency

- High thermal shock resistance

- Suitable for applications up to 900°C

- First installation in 1992

Cerafil® GR Series

- Strong, bio-soluble MgAl mineral fiber

- Environmentally friendly and non-hazardous to humans

- 99.99% dust removal efficiency

- Temperature resistant up to 700-750℃

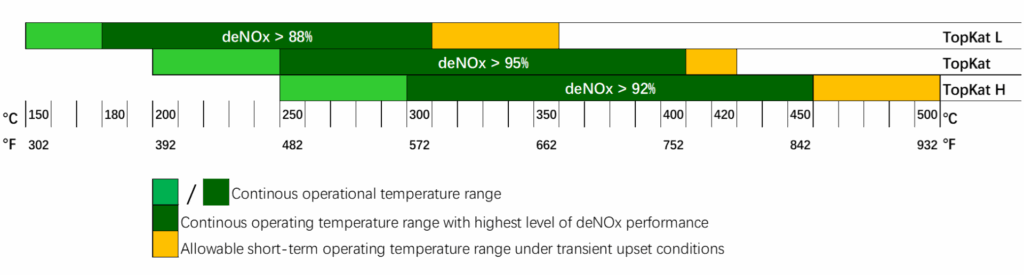

Catalytic filters – Cerafil® TopKat™ Series

Cerafil® TK Series

- 99.99% dust removal efficiency with simultaneous removal of hazardous gases

- High NOx reduction efficiency (up to 95%) across 180–500°C temperature range

- Demonstrated long-term stability in industrial applications

- World’s first large-scale industrial application launched in 2009

- Now established as the benchmark for catalytic ceramic filtration worldwide

Key Features

- Highest particulate and NOx removal performance to meet stringent emission standards

- Inert oxide formulation for excellent corrosion resistance

- Maintains gas temperature for downstream processes or heat recovery

- Effective acid gas scrubbing when combined with dry sorbents

- Long service life (up to 10 years in demanding applications)

- Rigid candles employed like fabric bags in filtration plant

- Robust ceramic design that avoids fabric filter limitations

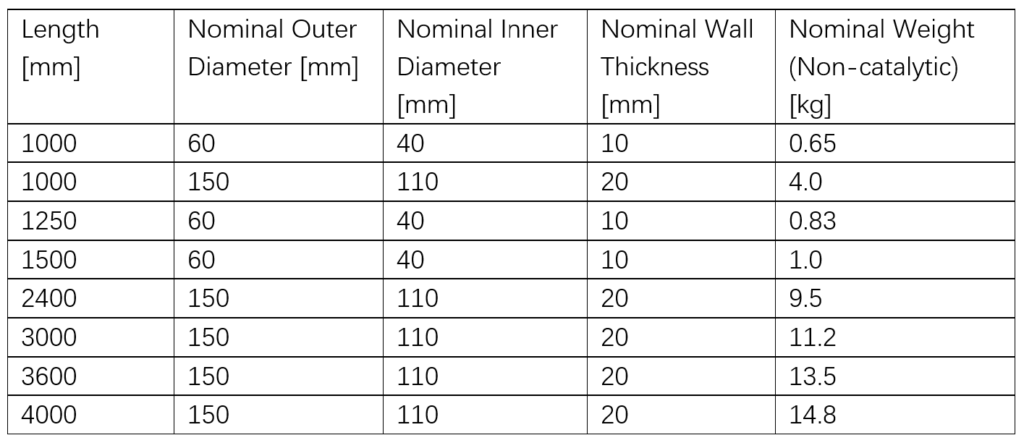

Dimensions & Design

Precision-formed to shape, ensuring dimensional accuracy and consistent performance.

Cerafil® deNOx Catalyst

Selection for Cerafil® TopKat Filter Elements

Cerafil® Applications

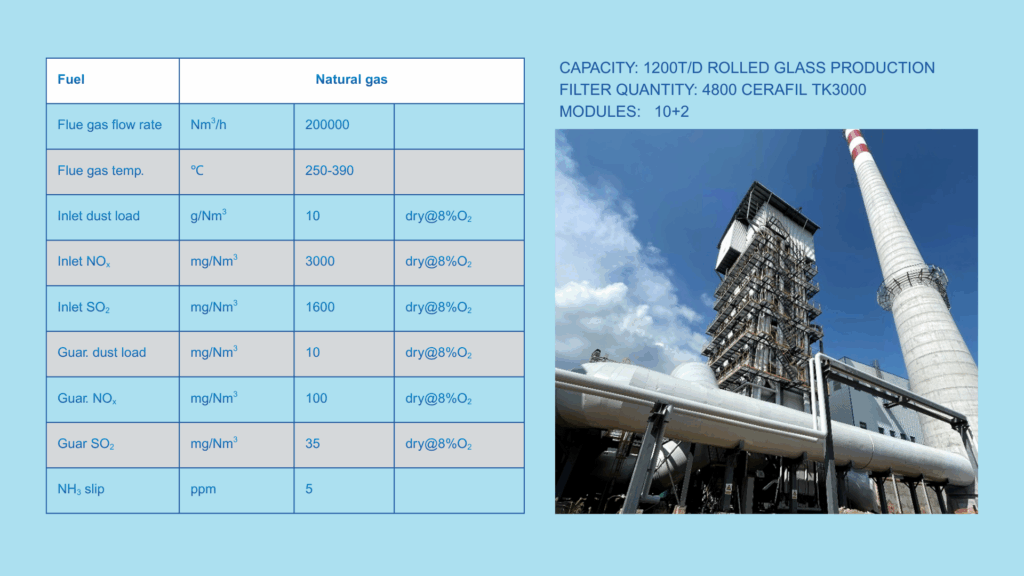

- Glass manufacturing

- Waste incineration (municipal, biomass, sewage sludge)

- Biomass combustion

- Cement and lime kilns

- Gasification and pyrolysis

- Metal smelting and mineral processing

- Marine exhaust cleaning

- Catalyst protection

Cerafil® Case Study – Glass Furnace

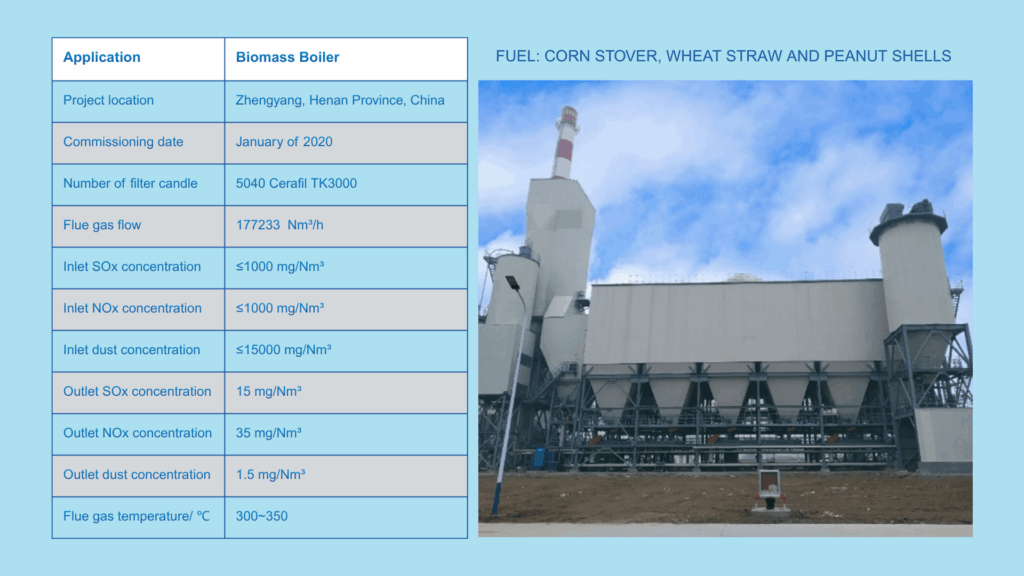

Cerafil® Case Study – Biomass Power Plant 30 MWel

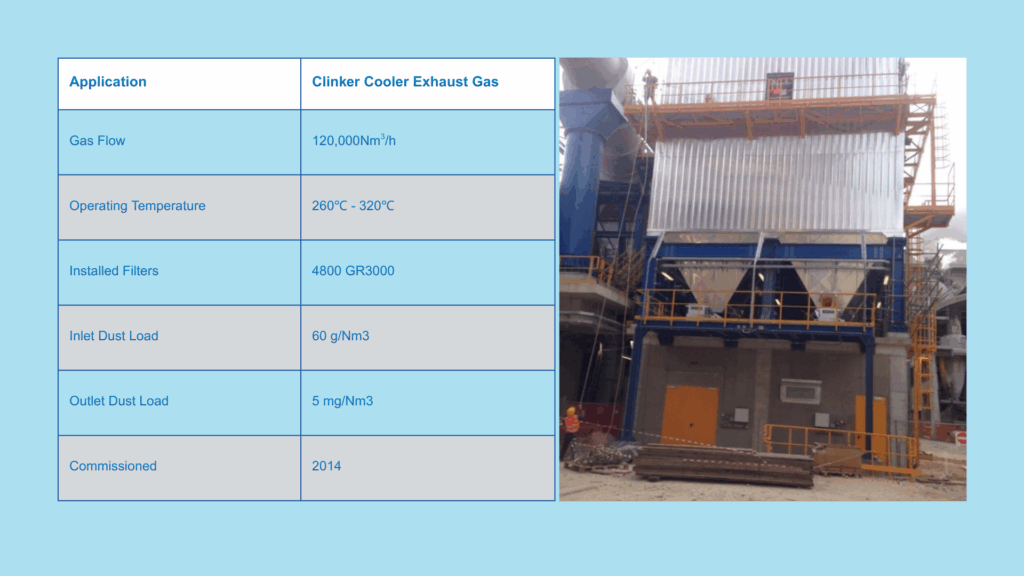

Cerafil® Case Study – Cement Plant in Italy

Cerafil® Filter Elements Brochure

Our Distributor:

Ceramic Filter Alliance (CFA)

220 Newport Center Drive, 11 – 165 Newport Beach, CA 92660 USA

(918) 605-5181

Website: https://ceramicalliance.com

Email: [email protected]