Hardware Spares

The quality and condition of your hardware spares has a direct impact on your process productivity and filtration efficiency. Clear Edge provides a complete filtration hardware solution to complement our filter media, including Pressure Filter Leaves, Ultraflo™ Disc Filter Sectors and Filter Press Plates, which are all manufactured to exacting standards and use the highest grade materials.

Filter Press Plates

Clear Edge’s range of filter press plates are custom designed and manufactured to help you achieve the highest performance from your filter presses. Just as replacing the filter media with a new set of Clear Edge’s filter press cloths increases a filter’s performance, replacing some or all the plates in a filter press can provide immediate and long-lasting performance benefits.

With decades of experience in filter press component engineering, Clear Edge offers plates and associated parts capable of enhancing filter press operations, reducing time and operational spend on maintenance, and lowering risk to personnel.

Performance

High quality of materials, years of experience, precision engineering and rigorous manufacturing standards mean that Clear Edge filter press plates can help your process deliver greater productivity and improved levels of process control. Whether your priority is throughput, cake washing, cake moisture or solids retention, Clear Edge filter press plates could be a significant step in achieving process excellence.

Reliability

Appropriately designed and manufactured filter press plates, will contribute to the reliability of a well operated process. Clear Edge’s technically trained team will assist you to select the right replacement filter plates, to help achieve enhanced reliability.

Safety Guaranteed

Low quality or damaged filter plates pose a safety risk to the personnel working with and around them. Clear Edge’s precision filter press plates, when properly used and maintained, will help negate the mechanical and pressure related risks a substandard plate pack represents.

Clear Edge Filter Press Cloths

Clear Edge is a vertically integrated industrial process filter media business. We weave, finish, fabricate and then support our filter press cloths in the applications they’re used. Our filter press cloths are relied upon by an extensive range of customers and industries around the world.

Offering a comprehensive range of market leading filter media and finished product design features, Clear Edge filter press cloths work in harmony with our filter press plates to drive excellence in your process.

Accompanying Products Range

- Membranes (diaphragms) in natural

- and compound rubbers

- Distribution rings (filling shoes)

- Wear parts

- Handles and fasteners

- O-rings, seals and gasket

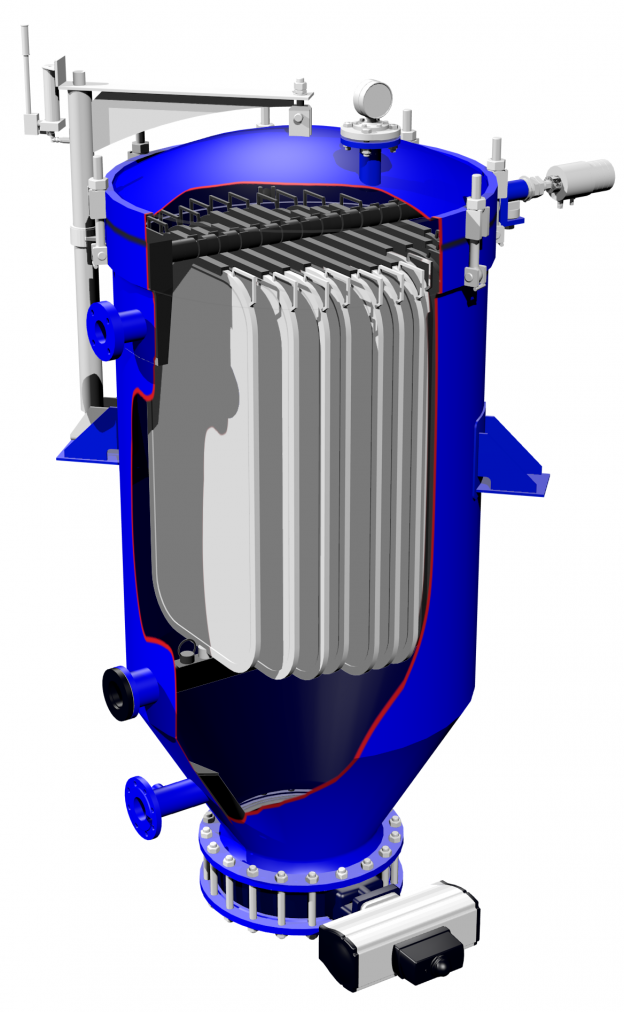

Pressure Filter Leaves

The quality and condition of the filter leaves has a direct impact on the productivity and filtration efficiency of any pressure leaf filter. Clear Edge, in conjunction with our Filtration Group partners, offers new high-performance pressure filter leaves and the refurbishment of your used leaves, to an “as new” standard.

Just as replacing the filter media with a new set of Clear Edge’s pressure leaf cloths increases the filter’s performance, replacing some or all the leaves in a pressure leaf filter can provide immediate and long-lasting performance benefits.

Performance

Whether brand new or rescreened, Clear Edge pressure filter leaves will provide an immediate elevation in the performance of your filter. Pressure filter leaves and the filter cloth they support (in most cases) are the most important components of a pressure leaf filter. Blockages, poor condition surfaces, deteriorated structural integrity or seal to the filter’s outlet will cause a host of problems. New or rescreened leaves will boost filtrate flow and therefore productivity and improve solids capture with higher filter surface integrity and lower bypass potential.

Reliability

We only use high quality materials when building new or rescreened pressure filter leaves, which combined with decades of experience and exceptional manufacturing standards means they deliver market leading operational life. The result is lower maintenance demand and less filter downtime as the leaves and filter media work for longer in your process.

Product Features

Range details

- Many mesh types and layer combinations available, suitable for both synthetic fabric and metallic mesh filtration surfaces, providing the right structure for efficient filtrate flow.

- Full range of frame types with riveted, welded or bolted closure to ensure a robust finish and high filtration efficiency.

- All nozzle types and centre hubs available to ensure leak free fitting to your filter.

- A range of steel types available to suit your process.

Rescreening

- The leaves function as new

- Save up to 40% compared to new leaves

- Leaves are thoroughly inspected prior to reassembly

- Many leaves can be rescreened twice

- Amafilter LFC Lochem and many other manufacturers’

leaves can be rescreened - We can handle many screen shapes and configurations

Clear Edge exclusive coated filter medias

- Versis™ – Vertical pressure leaf filters

- Cricketfilter® – polishing / heel, wet and dry discharge filters

ProGuard™ FR Series – Automatic backflushing filters

Clear Edge Pressure Leaf Filter Cloths

Clear Edge is a vertically integrated industrial process filter media business. We weave, finish, fabricate and then support our pressure leaf filter cloths in the applications they’re used. Our pressure leaf filter cloths are relied upon by an extensive range of customers and industries around the world.

Offering a comprehensive range of market leading filter media and finished product design features, Clear Edge pressure leaf filter cloths work in harmony with our pressure filter leaves to drive excellence in your process.

For more information on our Pressure Filter Leaves, contact the team

Technical Features

The Ultraflo™ polymer inner support grid provides the perfect structure for drainage of filtrate from the back of the filter media and then clearance to the vacuum system. Thicker filter cake is collected in the forming zone and then efficiently dried, elevating the quantity of slurry processed and the quality of filter cake.

Ultraflo™ disc sectors provide unsurpassed support to the filter media, reducing the chance of the sector causing a hole in the disc filter bag. Couple this with the inherent robustness of Ultraflo™ and you are likely to see a significant reduction in downtime and the associated productivity benefits.

Safety

The polymer support grids are not only essential to the enhanced productivity Ultraflo™ can offer, but also to its reduced weight when compared to a fully steel sector. By their nature, disc sectors must be manually handled when being removed from the filter, reclothed and then replaced. Lower weight sectors provide reduced injury risk during these procedures.

Reliability Guaranteed

One of the most damaging issues for any operation is unreliable equipment. Inferior quality or deteriorating sectors can impact the reliability of a disc filter significantly. The Ultraflo™ outer steel frame and inner polymer support grid are built with consideration to testing corrosive and abrasive environments hence prolonging the operational life of both the sector and the filter media.

When eventually an Ultraflo™ disc filter sector does suffer damage, the inner support grid can be replaced (optional feature), extending the sector’s operational life at minimal cost, a feature not possible with fully metallic or fully plastic sectors.

Benefits of Clear Edge’s Ultraflo

- Up to 40% lighter* than full steel sectors

- Sector removal, reclothing and replacement is quicker and easier reducing operator

- injury risk.

- Potentially lower energy consumption during filter operation.

- Unique steel and polymer design

- Exceptional filtrate clearance delivers larger, dryer filter cakes, better cake release and therefore increased throughput.

- The polymer grid is the perfect surface to support the disc bag filter media helping extend its operational life and therefore machine availability.

- Option of removeable end section to allow replacement of the polymer support grids and interior cleaning of the Ultraflo™ sector.

- Robust high-quality materials and expert custom-made products.

- Improved filter reliability.

- Made specifically to fit your filter.

Markets

With a history of use in tough process environments including alumina, iron ore, copper concentrate and paste dewatering and available with mild, carbon or stainless-steel outer frames, Ultraflo™ is suited to a wide range of challenging applications. Discuss your process conditions with your Clear Edge representative.